Auto Carrier Faces $70 Million Loss From US Port Fees

Table of Contents

The Impact of Increased US Port Fees on Auto Carriers

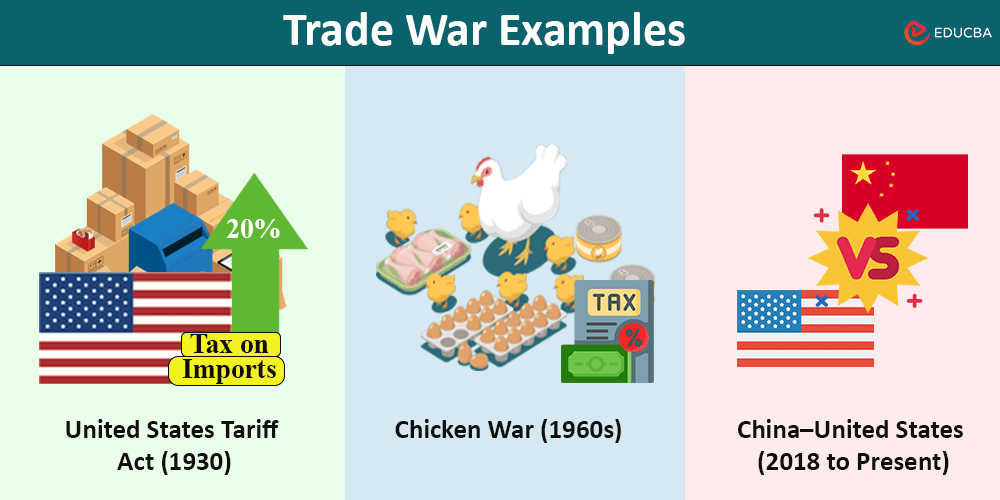

US port fees are a complex structure, encompassing various charges levied by port authorities. These fees are influenced by numerous factors, including labor costs, necessary infrastructure upgrades, and increasingly significant congestion surcharges. The recent surge in these fees is creating a crippling burden for auto carriers, significantly impacting their bottom line.

- Specific Fee Increases: Reports indicate increases ranging from 15% to 30% in certain port fees over the past year, depending on the port and the type of cargo. This translates to millions of dollars in added expenses for large auto carriers.

- Ripple Effect: These added costs are inevitably passed down the supply chain, resulting in higher prices for consumers. Furthermore, the financial strain on auto carriers can lead to delays in vehicle deliveries, impacting sales and customer satisfaction. Reduced profitability puts pressure on the entire automotive industry.

Congestion at Major US Ports Exacerbates the Problem

The situation is further aggravated by persistent congestion at major US ports, particularly Los Angeles and Long Beach. These ports, crucial gateways for vehicle imports, are facing unprecedented bottlenecks.

- Contributing Factors: Supply chain disruptions caused by the pandemic, increased import volumes driven by consumer demand, and labor shortages at ports all contribute to these issues.

- Increased Dwell Times: Congestion leads to significantly increased dwell times – the time a vehicle spends waiting at the port before being transported. This directly translates into higher storage costs and further amplifies the financial impact of already elevated port fees. Statistics show dwell times have increased by an average of 40% in some ports.

- Examples of Delays: One specific example of the financial consequences includes a recent delay of 10 days for a shipment of 500 vehicles, costing the auto carrier an estimated $250,000 in additional storage and port fees.

Strategies Auto Carriers Employ to Mitigate Rising Costs

Faced with these challenges, auto carriers are actively exploring strategies to mitigate the impact of rising port fees.

- Negotiating Better Rates: Some carriers are attempting to negotiate better rates with port authorities, though success is limited due to the high demand for port services.

- Optimizing Shipping Routes: Re-routing shipments to less congested ports, though potentially adding distance and time, can sometimes offer cost savings.

- Supply Chain Efficiency: Implementing leaner and more efficient supply chain processes can reduce the overall costs and improve the flow of vehicles.

- Alternative Ports: Exploring alternative ports of entry, even if farther from major markets, may provide a temporary solution, though this is often geographically challenging.

- Technology Solutions: Investing in technology for improved logistics, real-time tracking, and predictive analytics can help optimize shipping schedules and minimize delays.

The effectiveness of these strategies varies greatly depending on factors beyond the carrier's control. Implementing these strategies also presents significant challenges, including limited negotiation power with port authorities, infrastructure constraints, and the substantial investments required in technology upgrades.

The Broader Implications for the Automotive Industry and Consumers

The financial pressures stemming from increased US port fees are not confined to auto carriers; they reverberate throughout the entire automotive industry and ultimately affect consumers.

- Higher Vehicle Prices: Increased shipping costs are inevitably passed on to consumers in the form of higher vehicle prices, impacting affordability and potentially slowing down vehicle sales.

- Supply Chain Disruptions: Persistent port congestion and elevated costs can lead to further supply chain disruptions, resulting in decreased vehicle availability and longer wait times for customers.

- Competitive Landscape: The increased costs place significant pressure on auto manufacturers' profit margins and create a challenging competitive landscape. Companies with more efficient logistics strategies will have a significant advantage.

- Long-Term Effects: Without effective intervention, these challenges could lead to decreased investment in the US automotive market, impacting domestic manufacturing and jobs.

Conclusion

The $70 million loss faced by this auto carrier serves as a stark warning of the devastating impact of soaring US port fees. Port congestion, increasing costs, and supply chain disruptions present significant challenges for the entire automotive industry and consumers. Understanding the intricacies of these issues and the strategies being employed to mitigate the impact are critical. Understanding the impact of rising US port fees is crucial for navigating the complexities of the automotive supply chain. Stay informed and adapt to the evolving landscape of automotive logistics.

Featured Posts

-

Three Years Of Data Breaches Cost T Mobile 16 Million

Apr 26, 2025

Three Years Of Data Breaches Cost T Mobile 16 Million

Apr 26, 2025 -

2700 Miles From Dc How Trumps First 100 Days Affected A Rural School

Apr 26, 2025

2700 Miles From Dc How Trumps First 100 Days Affected A Rural School

Apr 26, 2025 -

Point72 Traders Exit As Emerging Markets Focused Fund Closes

Apr 26, 2025

Point72 Traders Exit As Emerging Markets Focused Fund Closes

Apr 26, 2025 -

Dow Futures China Economy And Todays Stock Market Tariff Impact

Apr 26, 2025

Dow Futures China Economy And Todays Stock Market Tariff Impact

Apr 26, 2025 -

Golds Record High Understanding The Trade War Impact On Bullion

Apr 26, 2025

Golds Record High Understanding The Trade War Impact On Bullion

Apr 26, 2025