Auto Carrier's Financial Hit: $70 Million Worst-Case Estimate Due To US Port Fees

Table of Contents

The $70 Million Estimate: A Deep Dive into the Numbers

The $70 million figure represents a potential catastrophic blow to the auto carrier's bottom line. This estimate is based on a projected increase in US port fees affecting approximately 100,000 imported vehicles. The cost increase per vehicle ranges from $500 to $700, depending on the vehicle size and type. This substantial rise isn't attributed to a single factor but a confluence of increased charges.

Specific examples of increased fees include:

- Increased container dwell fees: Longer waiting times at ports due to congestion result in significantly higher storage charges.

- Higher chassis rental charges: The cost of renting the chassis needed to transport containers has also increased dramatically.

- Surcharges due to port congestion: Delays and inefficiencies at congested ports lead to various surcharges imposed by shipping companies and terminal operators.

- Administrative processing fees: Increased paperwork and bureaucratic hurdles contribute to additional administrative costs.

These various fee components add up quickly, placing immense pressure on the auto carrier's profitability and potentially impacting the entire automotive supply chain.

Impact on the Automotive Supply Chain: Ripple Effects Across the Industry

The impact of these increased US port fees extends far beyond the auto carrier itself. The ripple effects are felt throughout the entire automotive supply chain:

- Increased vehicle prices: The added costs will inevitably be passed on to consumers, leading to higher vehicle prices.

- Reduced consumer demand: Higher prices can dampen consumer demand, leading to slower sales and potential inventory buildup.

- Potential manufacturing slowdowns: Reduced demand might force manufacturers to slow down production lines, impacting employment and economic growth.

- Layoffs in logistics and dealerships: The economic downturn caused by higher prices and reduced demand can lead to layoffs in logistics companies and dealerships.

Delays in vehicle delivery due to increased port congestion further exacerbate the problem. This disruption can disrupt the entire production schedule and cause further financial losses for all stakeholders. The consequences of these increased US port fees pose a serious threat to the stability of the US automotive industry.

Strategies for Mitigation: How Auto Carriers Can Adapt

To mitigate the devastating financial impact of the increased US port fees, auto carriers must explore several strategies:

- Negotiating lower fees with port authorities: Direct negotiations with port authorities to secure more favorable rates are crucial.

- Exploring alternative shipping routes (e.g., rail): Shifting some cargo to rail transport could reduce reliance on congested ports.

- Investing in supply chain optimization software: Advanced software can help streamline logistics, reduce delays, and improve efficiency.

- Lobbying for government support and policy changes: Advocating for government intervention to address port congestion and fee structures is essential.

The Role of Technology in Mitigating the Crisis

Technology plays a crucial role in mitigating the crisis. AI-powered route optimization can identify the most efficient shipping paths, minimizing delays and associated costs. Predictive analytics can help anticipate port congestion and allow for proactive adjustments to shipping schedules. Investing in these technologies offers long-term benefits, improving efficiency, reducing costs, and enhancing overall supply chain resilience. This technological investment is not just a cost but a crucial step towards long-term sustainability and profitability within the volatile landscape of automotive shipping.

Conclusion

The increased US port fees pose a significant financial burden on auto carriers, with potential consequences rippling through the entire automotive supply chain. The $70 million worst-case estimate underscores the urgency of finding effective solutions. Collaboration between stakeholders, including auto carriers, port authorities, and the government, is essential. Proactive measures, including negotiation, route diversification, technological investments, and policy advocacy, are crucial to mitigating the impact of these escalating fees. To ensure the health of the US automotive industry, proactive steps to address the issue of US port fees must be taken immediately. We urge businesses to explore strategies to mitigate the impact of increased port fees and investigate potential solutions for efficient automotive shipping, focusing on finding effective US port fee solutions and automotive shipping cost management to minimize the impact of increased import costs.

Featured Posts

-

Navigating The Trump Era The Upcoming Challenges For The Federal Reserve Chair

Apr 26, 2025

Navigating The Trump Era The Upcoming Challenges For The Federal Reserve Chair

Apr 26, 2025 -

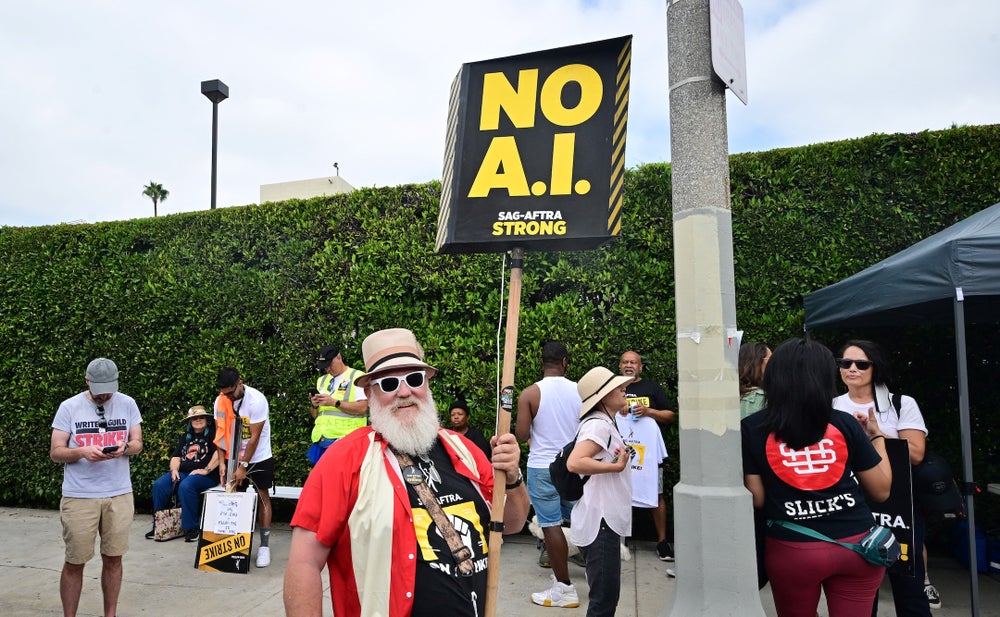

Hollywood Production Grinds To Halt As Actors Join Writers On Strike

Apr 26, 2025

Hollywood Production Grinds To Halt As Actors Join Writers On Strike

Apr 26, 2025 -

End Of Ryujinx Nintendo Contact Forces Emulator Shutdown

Apr 26, 2025

End Of Ryujinx Nintendo Contact Forces Emulator Shutdown

Apr 26, 2025 -

La Fire Aftermath Price Gouging Allegations Surface Selling Sunset Star Speaks Out

Apr 26, 2025

La Fire Aftermath Price Gouging Allegations Surface Selling Sunset Star Speaks Out

Apr 26, 2025 -

From Egypt To The Nfl Ahmed Hassaneins Historic Bid

Apr 26, 2025

From Egypt To The Nfl Ahmed Hassaneins Historic Bid

Apr 26, 2025