Dow's Construction Delay Impacts Major Canadian Project: Volatility Analysis

Table of Contents

The Scope of Dow's Delay and its Canadian Impact

This analysis centers on the delayed construction of the "Northern Lights" hydroelectric dam project situated in northern Ontario. Dow Chemical, a major supplier of specialized polymers crucial for the dam's water sealing and turbine components, experienced unforeseen production setbacks at its Sarnia plant due to unexpected regulatory hurdles. This delay, beginning in Q2 2023, is currently estimated to extend the project timeline by at least six months.

- Specific delayed materials: High-performance epoxy resins and specialized polyurethane sealants.

- Quantifiable impact on project timeline: A minimum six-month delay, potentially extending to nine months depending on the resolution of the regulatory issues.

- Geographic location of the affected project: Northern Ontario, specifically near the town of Thunder Bay.

Financial Volatility Analysis: Cost Overruns and Budgetary Impacts

The six-month delay translates into significant financial repercussions for the Northern Lights project. These include:

- Increased labor costs: Extended employment contracts for construction workers, engineers, and project managers add considerable expense. Estimates place this at approximately CAD 15 million.

- Material price fluctuations: The delay has exacerbated existing supply chain issues, leading to price increases for alternative materials and potentially delaying the procurement of Dow’s materials further once available. This adds an estimated CAD 8 million to the project cost.

- Penalties for missed deadlines: Contractual penalties with the provincial government for late completion are estimated at CAD 20 million.

- Impact on project profitability and return on investment (ROI): The cumulative cost overruns threaten the project's profitability and delay its anticipated ROI by at least two years.

The project's insurance coverage is currently under review, with potential claims related to the delay potentially covering a portion of the additional costs, but this is not yet certain. Investor confidence has also been shaken, leading to concerns about securing additional funding for the project's completion.

Logistical Volatility: Supply Chain Disruptions and Project Management Challenges

The Dow delay triggered a cascade of logistical challenges:

- Alternative sourcing strategies explored: The project team explored alternative suppliers for the specialized polymers, but finding comparable quality within the required timeframe proved difficult and expensive, ultimately delaying the procurement further.

- Challenges in managing the project timeline and workforce: Rescheduling construction phases and re-allocating workforce resources proved complex, requiring extensive replanning and communication.

- Impact on project milestones and completion dates: Several key milestones have been missed, pushing back the project's completion date significantly, impacting downstream projects relying on the dam's completion.

Reputational Volatility: Public Perception and Stakeholder Relations

The delay has exposed the project to reputational risks:

- Potential negative press coverage and its impact: Negative media coverage highlighting cost overruns and project delays has damaged public perception.

- Strategies for managing stakeholder expectations and communication: The project team has implemented transparent communication strategies with stakeholders to manage expectations, however, the damage to public trust may take significant time to repair.

- Long-term reputational risks associated with the delay: The delay could lead to reduced public confidence in future hydroelectric projects and potentially impact the government's credibility.

Conclusion: Mitigating Future Volatility from Dow's Construction Delays in Canadian Projects

This analysis of Dow's Construction Delay Impacts on the Northern Lights project highlights the significant financial, logistical, and reputational risks associated with supply chain disruptions. To mitigate similar risks in future projects, several crucial steps are necessary:

- Diversification of suppliers to reduce reliance on single vendors.

- Robust risk assessment protocols incorporating thorough supply chain analysis.

- Comprehensive contingency planning that addresses potential delays and includes alternative sourcing strategies.

- Transparent communication with all stakeholders to manage expectations effectively.

Understanding the vulnerabilities associated with Dow's construction delay impacts and similar situations is crucial for the success of future Canadian projects. We urge readers to delve deeper into construction delay analysis and risk mitigation strategies to enhance project resilience and minimize the impact of unforeseen circumstances.

Featured Posts

-

The Story Behind Ariana Grandes Drastic Hair And Tattoo Changes

Apr 27, 2025

The Story Behind Ariana Grandes Drastic Hair And Tattoo Changes

Apr 27, 2025 -

Pfcs Complaint To Eo W Gensol Engineering Accused Of Document Falsification

Apr 27, 2025

Pfcs Complaint To Eo W Gensol Engineering Accused Of Document Falsification

Apr 27, 2025 -

Teslas Canadian Price Hike Impact Of Pre Tariff Inventory Sales

Apr 27, 2025

Teslas Canadian Price Hike Impact Of Pre Tariff Inventory Sales

Apr 27, 2025 -

Zuckerbergs Leadership In A Trumpian America

Apr 27, 2025

Zuckerbergs Leadership In A Trumpian America

Apr 27, 2025 -

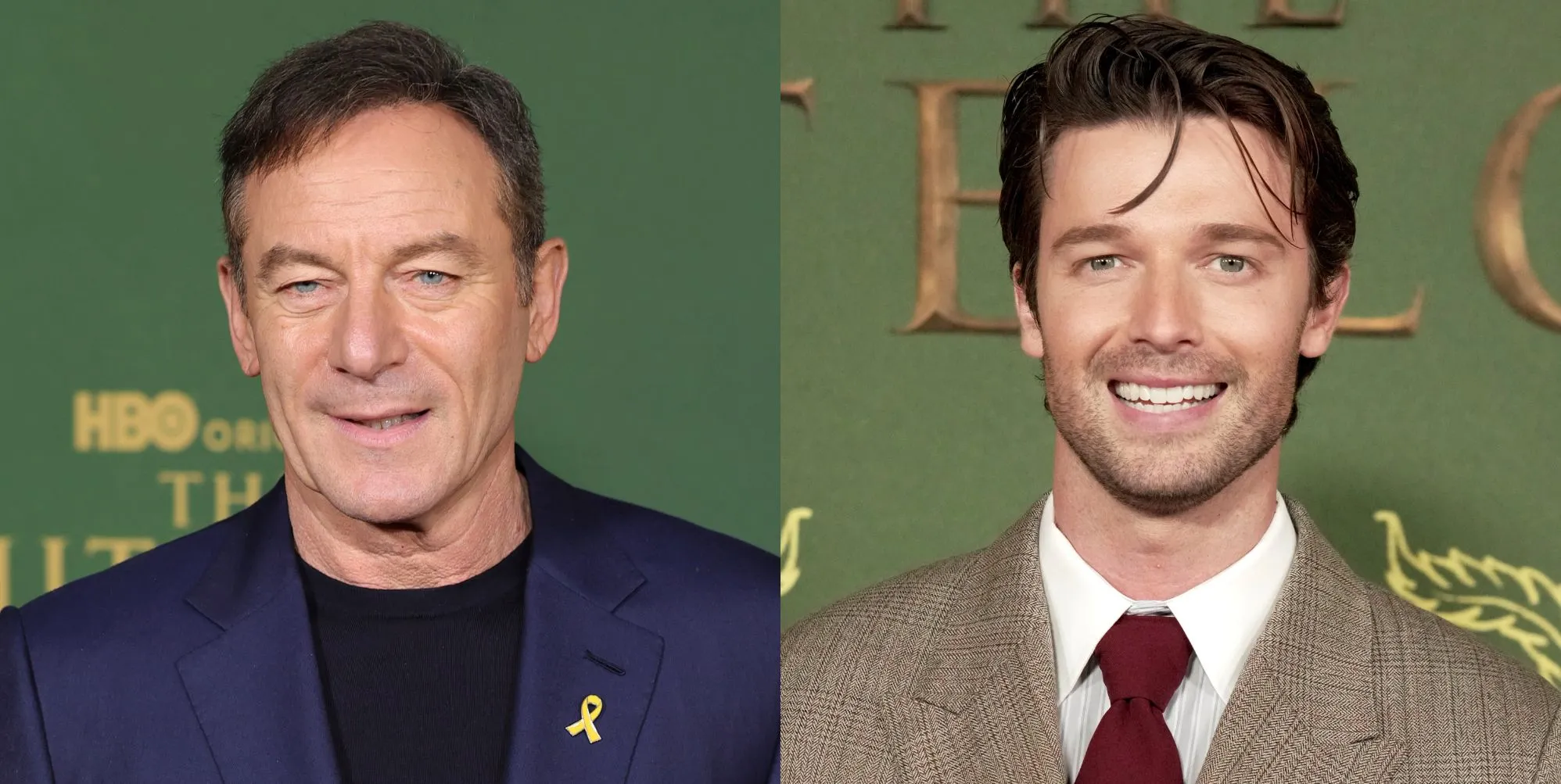

White Lotus And Ariana Grande Patrick Schwarzeneggers Surprising Connection Revealed

Apr 27, 2025

White Lotus And Ariana Grande Patrick Schwarzeneggers Surprising Connection Revealed

Apr 27, 2025