Tesla's Optimus Robot: China's Rare Earth Restrictions Cause Delays

Table of Contents

China's Dominance in Rare Earth Minerals and its Geopolitical Implications

China's near-monopoly on rare earth element mining and processing presents a significant geopolitical challenge. These elements, crucial for a vast array of high-tech applications, are not evenly distributed globally. China's control over this vital resource gives it considerable leverage in international relations and significantly impacts the global technology landscape. The strategic importance of rare earths is undeniable, particularly within the burgeoning field of robotics, where they are essential for powerful and efficient motors, sensors, and actuators. This dominance directly affects companies like Tesla, whose ambitious Optimus project relies heavily on these materials.

- China controls over 60% of global rare earth production, a figure that has fluctuated but consistently remains dominant.

- Rare earths are crucial components in Optimus' motors, sensors, and actuators, impacting its performance and functionality.

- Export restrictions implemented by China directly impact the global supply and cause price volatility, creating uncertainty for manufacturers.

- Geopolitical tensions and trade disputes influence China's willingness to cooperate, leading to unpredictable supply chains and potential delays.

This dominance creates a vulnerable position for Tesla and other tech companies reliant on a steady supply of these essential minerals. The implications extend beyond simple cost fluctuations; it involves potential production halts, project delays, and a reassessment of global supply chain strategies.

The Specific Rare Earth Elements Affecting Optimus Robot Production

The functionality of Tesla's Optimus robot is intricately linked to several specific rare earth elements. Neodymium and dysprosium, for example, are critical components in the powerful permanent magnets used in the robot's motors. These magnets are responsible for the precise movements and strength required for Optimus to perform its intended tasks. Without a reliable supply of these elements, production faces significant challenges.

- Neodymium: Primarily used in high-strength permanent magnets within the robot's actuators and motors, significantly impacting its mobility and power.

- Dysprosium: Plays a crucial role in enhancing the magnetic properties of neodymium magnets, ensuring they maintain their strength even at high temperatures.

- Other rare earth elements, such as praseodymium and terbium, contribute to the functionality of various sensors and electronic components within the robot.

The shortage of these specific elements directly impacts the production timeline. A lack of neodymium, for instance, could result in delays in motor production, causing a ripple effect throughout the entire assembly process. The reliance on these specific rare earth elements underscores the vulnerability of advanced robotics to geopolitical factors. Potential alternative materials exist, but they often come with limitations in terms of performance, cost, and availability.

Tesla's Strategies to Mitigate the Impact of Rare Earth Restrictions

Tesla is actively exploring several strategies to mitigate the impact of China's rare earth restrictions and ensure a stable supply of these critical materials for Optimus production. These strategies aim to reduce reliance on a single source and secure a more resilient supply chain.

- Diversification of supply chains: Tesla is actively pursuing agreements with rare earth mining companies in Australia, the United States, and other countries to diversify its sources.

- Investment in rare earth mining and processing technologies: Direct investments in mining and refining operations could reduce reliance on external suppliers.

- Development of alternative materials and designs: Research into alternative materials and magnet designs that require fewer or no rare earths is crucial for long-term independence.

- Collaboration with other companies and governments: Partnerships can facilitate access to resources and expertise, fostering a more collaborative approach to supply chain management.

- Lobbying for policy changes: Advocating for policies that encourage domestic rare earth production and processing is vital for achieving long-term supply chain security.

The effectiveness of these strategies remains to be seen. The challenges are significant, ranging from the time-consuming nature of establishing new mining operations to the technological hurdles of developing suitable alternative materials. However, Tesla's proactive approach highlights the necessity of a diverse and robust supply chain in the face of geopolitical uncertainty.

The Impact on Tesla's Production Timeline and Market Position

The rare earth constraints are likely to cause significant delays in the Optimus robot's launch. These delays have substantial implications for Tesla's financial performance and its position within the competitive robotics market.

- Estimated delay: The extent of the delay is difficult to quantify precisely, but it could range from several months to even years, depending on the success of Tesla's mitigation strategies.

- Impact on Tesla's stock price: Any significant delay could negatively affect investor confidence and potentially lead to a drop in Tesla's stock price.

- Competitive advantage lost: Competitors are rapidly advancing their own robotics projects, and delays could allow them to seize market share.

- Long-term consequences: A prolonged delay could significantly impact Tesla's broader automation strategy and its overall long-term vision.

Conclusion

China's dominance in rare earth minerals presents a significant challenge to Tesla's Optimus robot project, leading to potential Tesla Optimus robot delays. The dependence on specific rare earth elements for critical robot components has highlighted the vulnerabilities of relying on a single source for these crucial materials. While Tesla is actively pursuing strategies to mitigate these risks, including supply chain diversification and the exploration of alternative materials, the challenges remain significant. The impact on Tesla's production timeline, financial performance, and market position could be substantial. Stay informed about the ongoing developments surrounding the Tesla Optimus robot delays and the evolving geopolitical landscape of rare earth mineral supply. Follow us for updates on the future of robotics and the impact of global supply chain dynamics.

Featured Posts

-

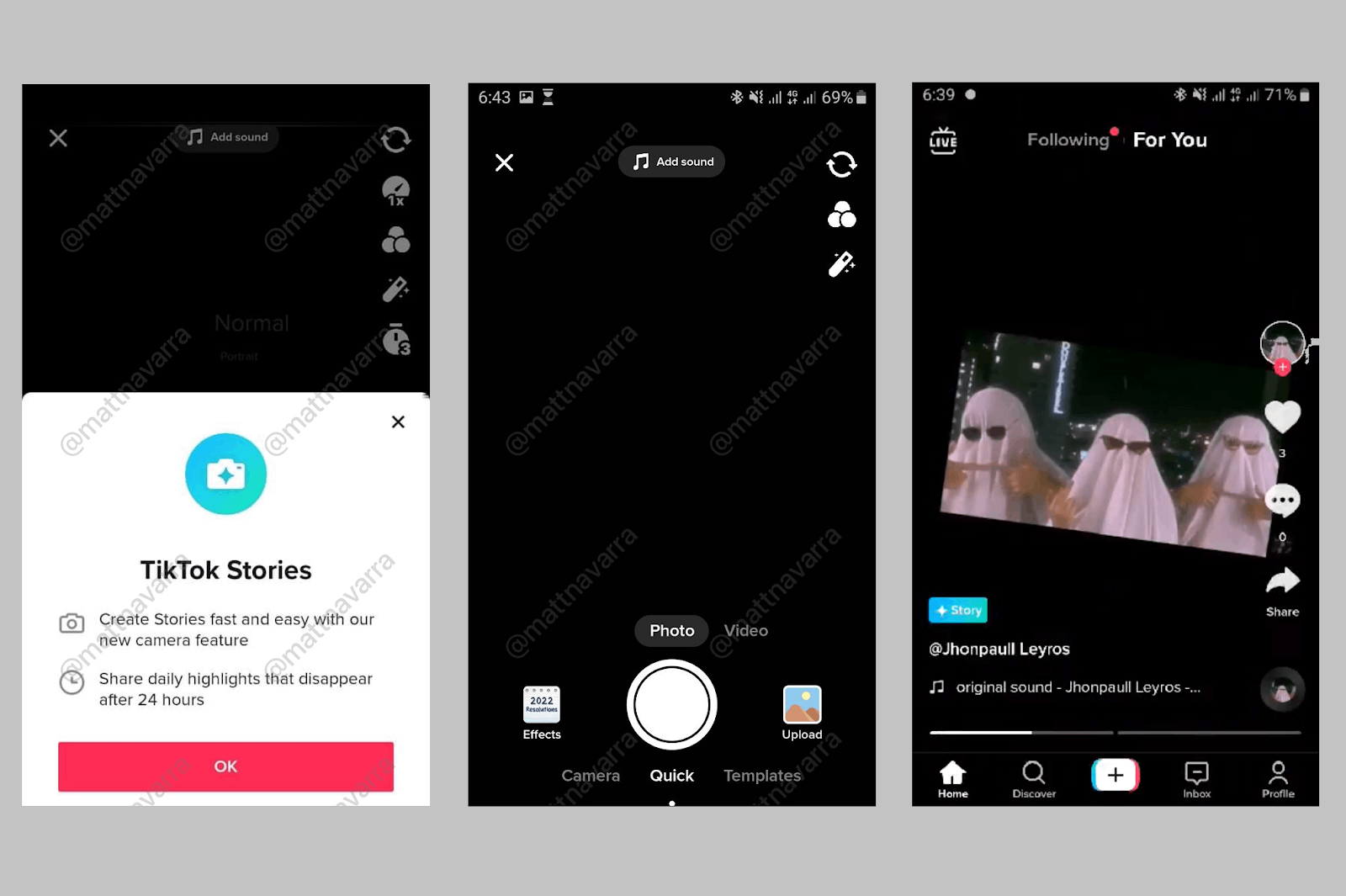

New Instagram App Aims To Poach Tik Tok Creators

Apr 24, 2025

New Instagram App Aims To Poach Tik Tok Creators

Apr 24, 2025 -

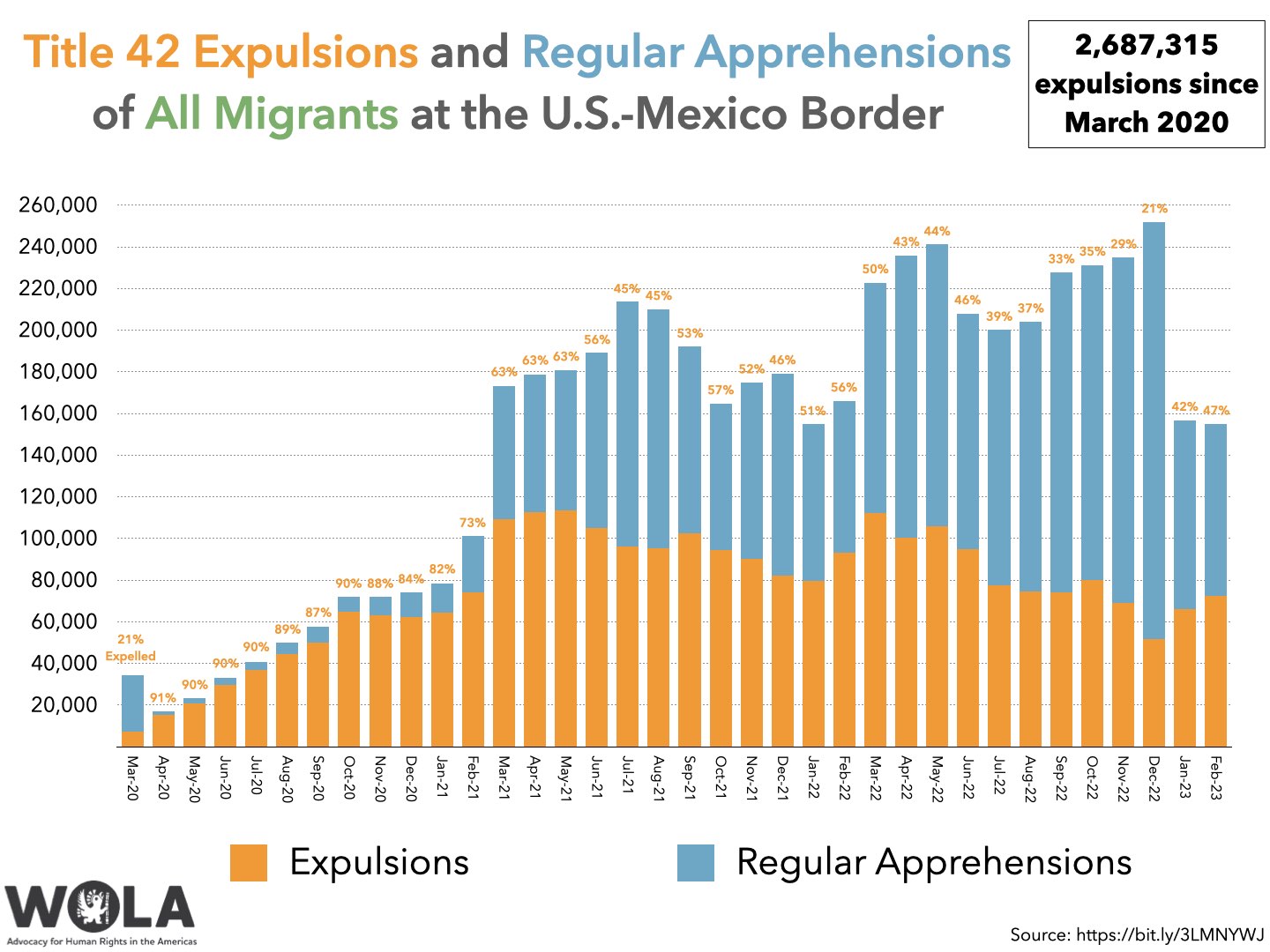

Fewer Border Crossings At Canada U S Border White House Report

Apr 24, 2025

Fewer Border Crossings At Canada U S Border White House Report

Apr 24, 2025 -

Herro Takes 3 Point Crown Garland And Okoro Win Skills Challenge

Apr 24, 2025

Herro Takes 3 Point Crown Garland And Okoro Win Skills Challenge

Apr 24, 2025 -

Sophie Nyweide Mammoth Noah Remembering A Talented Young Actress

Apr 24, 2025

Sophie Nyweide Mammoth Noah Remembering A Talented Young Actress

Apr 24, 2025 -

The Bold And The Beautiful Next 2 Weeks Preview Hope Liam And Steffys Explosive Storylines

Apr 24, 2025

The Bold And The Beautiful Next 2 Weeks Preview Hope Liam And Steffys Explosive Storylines

Apr 24, 2025