The Difficulty Of Automating Nike Sneaker Production: A Technological Deep Dive

Table of Contents

The Complexity of Sneaker Manufacturing

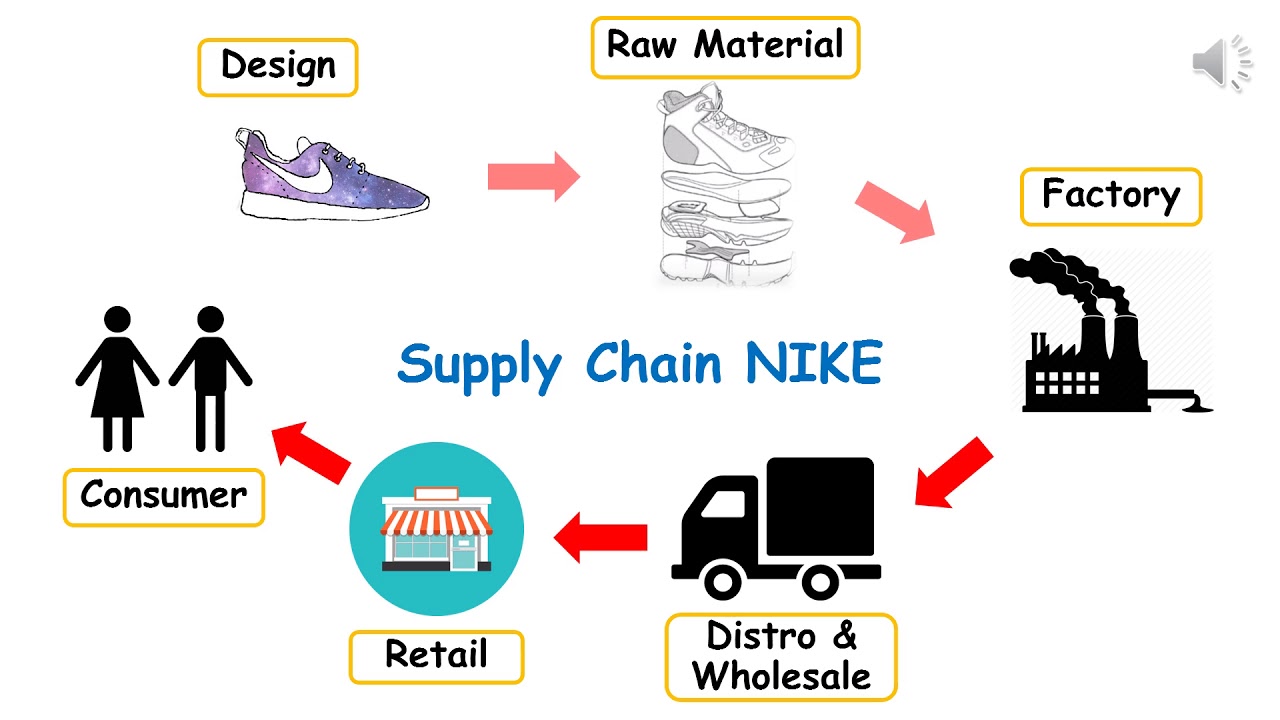

Manufacturing a Nike sneaker involves a surprisingly intricate series of steps, far beyond the casual observer’s understanding. From initial design and material sourcing to the final assembly and quality control, each stage presents unique challenges for automation. Let’s break down the complexity:

- Diverse Materials: Sneakers are made from a wide range of materials, including leather, various synthetics, textiles, and rubber, each requiring specialized handling and processing techniques. Automating the handling and processing of these diverse materials presents a significant challenge.

- Precision Cutting and Stitching: Achieving the precise cuts and consistent stitching needed for optimal fit and durability is crucial. The slightest imperfection can impact both comfort and the structural integrity of the shoe. This requires a level of precision that current automation technologies struggle to match.

- Complex Assembly Processes: Assembling a sneaker involves numerous components and steps. From attaching the sole to the upper, to installing laces and eyelets, the process is intricate and requires a high degree of dexterity and coordination.

- Stringent Quality Control: Nike maintains rigorous quality control measures to ensure consistency and uphold its brand standards. Automated systems would need to be equally rigorous and capable of identifying even minor defects.

- Variability in Designs and Models: Nike produces a vast array of sneaker designs and models, each with unique features and assembly requirements. Adapting automation systems to handle this variability presents a significant challenge. This flexibility is a key aspect of Nike's brand identity, requiring adaptability in any automation strategy.

Technological Limitations in Automation

While robotic automation has made strides in various manufacturing sectors, several technological limitations hinder the complete automation of Nike sneaker production. These limitations stem primarily from the dexterity and precision demanded by the process:

- Dexterity Challenges: Replicating the dexterity and fine motor skills of the human hand for tasks such as stitching, gluing, and intricate assembly remains a significant hurdle for robotics. Current robotic systems lack the adaptability needed to handle the nuanced movements required for these tasks.

- Material Variability: Adapting robots to handle the diverse range of materials and their varying properties is challenging. Each material requires specific handling techniques, and variations in material consistency can further complicate automated processes.

- High Investment Costs: Implementing advanced robotics and automation systems involves substantial upfront investment costs, including purchasing and installing the robots, integrating them with existing infrastructure, and training personnel.

- Integration Challenges: Integrating diverse automation systems into an existing manufacturing infrastructure can be complex and time-consuming, requiring significant expertise in robotics, software engineering, and manufacturing processes.

- Software Limitations: The lack of readily available, adaptable software for controlling and managing the complex assembly processes further limits the feasibility of complete automation. Developing such software requires significant time and resources.

The Role of Human Labor in Sneaker Production

Despite advancements in automation technology, human labor remains essential in Nike sneaker production. The expertise and adaptability of skilled workers are invaluable:

- Specialized Skills: Highly skilled workers possess the dexterity, precision, and creativity needed for complex tasks that current automation cannot readily replicate. These skills are especially crucial in handling intricate assembly steps and addressing unexpected issues during production.

- Quality Control Expertise: Human inspectors play a vital role in ensuring the quality and consistency of the finished product, identifying defects that automated systems might miss. This human element is critical for maintaining Nike’s high standards.

- Problem-Solving and Adaptability: Human workers can adapt quickly to unexpected problems or variations in materials and processes, something that is still difficult for automated systems to achieve. This adaptability is crucial for efficient and effective production.

- Retraining and Job Displacement: The introduction of automation requires careful consideration of the impact on workers, including the need for retraining programs to equip them with new skills and mitigate potential job displacement.

- Human Oversight: Even in partially automated systems, human oversight is essential for monitoring the performance of automated systems, ensuring quality control, and making necessary adjustments. This human element remains critical for maintaining consistency and upholding brand standards.

Addressing the Sustainability Factor in Automation

While automation offers the potential for increased sustainability through reduced waste and energy consumption, it's crucial to consider the environmental impact of producing and disposing of the robots themselves. The manufacturing and lifecycle of robotic systems themselves have an environmental footprint that needs careful assessment and optimization. Sustainable automation requires a holistic approach encompassing the entire lifecycle of the robotic systems.

Future Possibilities and Emerging Technologies

Despite the current limitations, advancements in robotics, AI, and related technologies offer the potential to overcome some of the challenges in automating Nike sneaker production:

- Advancements in Soft Robotics: Soft robotics, which uses flexible materials and actuators, could enhance the dexterity and adaptability of robots for handling delicate tasks.

- AI-Powered Vision Systems: Advanced AI-powered vision systems could significantly improve automated quality control by identifying even minor defects with high accuracy.

- Improved Machine Learning: Machine learning algorithms are becoming increasingly sophisticated, enabling robots to adapt more effectively to variations in materials, designs, and production processes.

- Collaborative Robots (Cobots): Cobots, designed to work alongside humans, could enhance productivity and efficiency by handling repetitive tasks while humans focus on more complex or creative aspects of production.

- Additive Manufacturing (3D Printing): 3D printing technology holds the potential for producing customized sneakers on demand, potentially revolutionizing the manufacturing process.

Conclusion

Automating Nike sneaker production presents significant challenges due to the complexity of the manufacturing process and the current limitations of automation technology. The dexterity and precision required for many tasks remain difficult for robots to replicate. While complete automation might still be some distance away, the continued importance of human labor is undeniable. However, emerging technologies like soft robotics, AI-powered vision systems, and collaborative robots offer promising avenues for overcoming some of these hurdles. The future of automating Nike sneaker production relies on continued research and development in these areas, as well as a thoughtful approach to integrating automation with human expertise. What are your thoughts on overcoming the challenges of automating Nike sneaker production? Join the conversation on the future of automating Nike sneaker production.

Featured Posts

-

Analyzing The Pan Nordic Defense Force Strengths And Weaknesses

Apr 22, 2025

Analyzing The Pan Nordic Defense Force Strengths And Weaknesses

Apr 22, 2025 -

Ai Transforms Repetitive Scatological Documents Into A Profound Poop Podcast

Apr 22, 2025

Ai Transforms Repetitive Scatological Documents Into A Profound Poop Podcast

Apr 22, 2025 -

Googles Search Monopoly Doj Returns To Court For Another Round

Apr 22, 2025

Googles Search Monopoly Doj Returns To Court For Another Round

Apr 22, 2025 -

Conclave 2023 Assessing Pope Francis Enduring Impact

Apr 22, 2025

Conclave 2023 Assessing Pope Francis Enduring Impact

Apr 22, 2025 -

Google Faces Doj In Renewed Court Battle Search Monopoly At Stake

Apr 22, 2025

Google Faces Doj In Renewed Court Battle Search Monopoly At Stake

Apr 22, 2025