Why Nike Shoe Manufacturing Remains A Challenge For Robots

Table of Contents

H2: The Complexity of Shoe Construction

Nike's iconic footwear isn't simply stitched together; it's a marvel of engineering. The complexity of shoe construction presents a major obstacle to complete robotic automation.

H3: Varied Materials and Processes

Creating a single Nike shoe involves a multitude of materials and processes. Consider the diverse range of materials: premium leather, synthetic fabrics like Flyknit, mesh textiles, and various cushioning technologies. The manufacturing process is equally varied, encompassing stitching, gluing, molding, and intricate assembly steps.

- Air Max cushioning: Requires precise injection molding and integration with the shoe's upper.

- Flyknit upper: Involves complex knitting techniques requiring high precision and adaptability.

- Leather overlays: Demand careful cutting, stitching, and alignment.

This heterogeneity of materials and processes makes it incredibly challenging to develop a single, universally applicable robotic system capable of consistent, high-quality production across the Nike product line. The variability in material properties necessitates different handling techniques, further complicating automation efforts.

H3: Dexterity and Precision Challenges

Many aspects of Nike shoe production demand a level of dexterity and precision that currently surpasses the capabilities of robotic systems.

- Stitching intricate patterns: The precise placement of stitches, particularly in decorative elements, requires fine motor skills that robots struggle to replicate.

- Attaching delicate components: The careful handling and placement of small, intricate parts, like logos or embellishments, necessitates a level of hand-eye coordination not yet achieved by robots.

- Quality control: Identifying subtle imperfections in materials or assembly requires human judgment and visual acuity.

Current robotic dexterity is limited. While robots excel at repetitive tasks, they struggle with the nuanced movements and adaptations required for the unpredictable variations in materials and processes during Nike shoe manufacturing.

H2: The Adaptability and Customization Factor

Nike's success hinges on its ability to adapt to changing trends and consumer preferences. This adaptability, however, poses a significant challenge for robotic automation.

H3: High-Volume, High-Variety Production

Nike produces a vast array of shoe models, sizes, and colors. Production lines must be highly adaptable to switch quickly between different styles, meeting fluctuating demand.

- Rapid reconfiguration: Robotic systems currently lack the speed and flexibility required for swift reconfiguration between different production runs.

- Inventory management: Efficiently managing the flow of materials and components for numerous shoe models presents a logistical challenge for robotic systems.

- Demand forecasting: Accurately predicting demand for different styles and sizes remains crucial for optimizing production, a process that is still heavily reliant on human expertise.

H3: The Rise of Personalized Footwear

The increasing demand for customized Nike shoes further complicates the picture. Personalized embroidery, unique color combinations, and bespoke design elements add another layer of complexity to the manufacturing process.

- Integration of customization: Current robotic systems struggle to integrate customizable elements efficiently into automated production lines.

- Data management: Handling the large volume of data associated with personalized orders presents significant computational and logistical challenges.

- Human intervention: The individualized nature of custom orders often necessitates a degree of human intervention, which compromises the efficiency gains of automation.

H2: Cost and Return on Investment (ROI)

The high cost of implementing and maintaining advanced robotic systems is a crucial factor hindering the full automation of Nike shoe manufacturing.

H3: High Initial Investment Costs

Integrating robotic systems requires substantial upfront investment.

- Hardware: The cost of purchasing high-precision robots and ancillary equipment is considerable.

- Software: Developing and implementing custom software for controlling robotic systems is expensive and time-consuming.

- Training and Maintenance: Training personnel to operate and maintain the robotic systems and the ongoing maintenance costs add to the financial burden.

H3: The Current ROI Limitations

Despite the potential for long-term cost savings, the current state of robotic technology may not yet provide a sufficient ROI for Nike.

- Human oversight: The need for human oversight and intervention often negates some of the potential cost benefits of automation.

- Technological limitations: The current limitations in robotic dexterity and adaptability restrict the scope of automation, making complete robotization economically unviable.

- Long-term potential: As robotic technology advances, the ROI of implementing these systems is likely to improve significantly, making the transition to a more automated Nike shoe production process more feasible.

3. Conclusion

The challenges facing complete automation of Nike shoe manufacturing are multifaceted. The complexity of shoe construction, the demand for adaptability and customization, and the currently high cost of implementation are significant hurdles. However, the future of robotics in Nike shoe manufacturing is not without optimism. Ongoing advancements in artificial intelligence, machine learning, and robotic dexterity hold the potential to address these challenges. The need for further research and development in areas such as improved dexterity, flexible manufacturing systems, and cost-effective robotic solutions is crucial to unlock the full potential of robotic integration in Nike shoe production automation. Continue to follow the progress of robotic technology in the footwear industry and its potential to eventually overcome the challenges of Nike shoe manufacturing. Further research into breakthroughs in robotic dexterity, adaptable manufacturing systems, and AI-driven quality control would significantly impact the future of Nike shoe production automation and robotic Nike manufacturing challenges.

Featured Posts

-

Live Stock Market Updates Dow Futures And Dollar Reaction To Trade News

Apr 22, 2025

Live Stock Market Updates Dow Futures And Dollar Reaction To Trade News

Apr 22, 2025 -

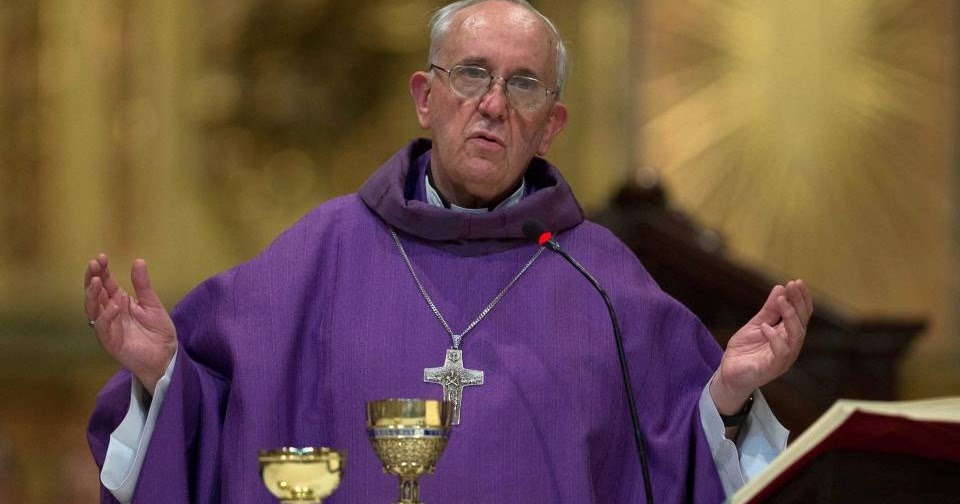

Papal Conclaves Explained The Process Of Electing A New Pope

Apr 22, 2025

Papal Conclaves Explained The Process Of Electing A New Pope

Apr 22, 2025 -

Anchor Brewing Companys Closure After 127 Years Impact On The Craft Beer Industry

Apr 22, 2025

Anchor Brewing Companys Closure After 127 Years Impact On The Craft Beer Industry

Apr 22, 2025 -

Examining The Synergies Sweden And Finlands Contribution To A Pan Nordic Defense

Apr 22, 2025

Examining The Synergies Sweden And Finlands Contribution To A Pan Nordic Defense

Apr 22, 2025 -

The End Of Ryujinx Developer Response To Nintendo Contact

Apr 22, 2025

The End Of Ryujinx Developer Response To Nintendo Contact

Apr 22, 2025